A Comprehensive Overview to the Sorts Of Ceramic Coating on the marketplace

Ceramic finishings have actually arised as a pivotal service across different sectors due to their one-of-a-kind properties and applications. As we discover the distinct features and applications of these finishes, the ramifications for performance and long life end up being progressively evident, elevating questions concerning which kind might best suit your needs.

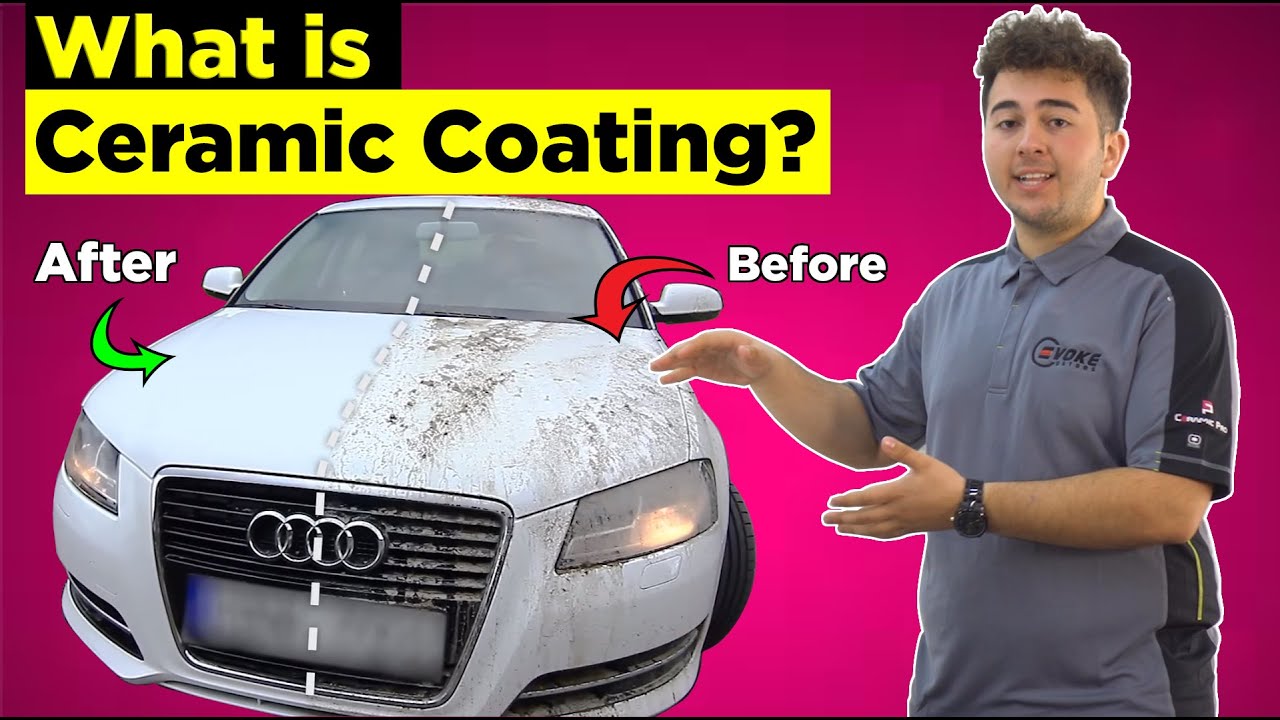

Understanding Ceramic Coatings

Ceramic finishings are sophisticated safety options that have gotten popularity in different markets, especially in aerospace and vehicle applications. These finishes are composed of a liquid polymer that, when treated, forms a durable, hydrophobic layer externally of the substrate. This layer gives boosted resistance to ecological pollutants, UV radiation, and chemical exposure, thereby extending the life and visual charm of the underlying material.

The fundamental part of ceramic layers is silica, which adds to their firmness and sturdiness. The application process typically involves surface area preparation, application of the covering, and curing, which can be attained with heat or UV light. As soon as cured, ceramic layers show exceptional bonding residential or commercial properties, enabling them to adhere strongly to a selection of surfaces, including metals, plastics, and glass.

Along with their protective attributes, ceramic finishes likewise offer convenience of maintenance. Their hydrophobic nature lowers the adherence of dust and crud, making cleaning less complex and less constant. In general, the fostering of ceramic finishes represents a substantial improvement in surface security modern technology, supplying both functional and aesthetic advantages throughout multiple fields.

Types of Ceramic Coatings

Different kinds of ceramic finishings are available, each developed to fulfill particular efficiency needs and applications. The most typical kinds consist of:

Silica-based Coatings, these coverings largely include silicon dioxide and are understood for their longevity and chemical resistance. They are extensively used in commercial and vehicle applications.

Titanium Dioxide Coatings: Renowned for their photocatalytic properties, titanium dioxide finishings are usually applied in settings where self-cleaning and antifungal homes are preferable, such as in structure products and auto finishes.

Zirconia Coatings are characterized by their high-temperature stability and thermal resistance, zirconia finishes are made use of in applications such as generator engines and high-performance automobile parts.

Alumina Coatings, Exhibiting outstanding firmness and thermal security, alumina finishings are regularly made use of in wear-resistant applications, consisting of reducing devices and industrial machinery.

Hybrid Coatings:Integrating the residential properties of different materials, hybrid coverings provide improved performance characteristics, making them suitable for unique and requiring applications.

Each sort of ceramic coating serves distinctive objectives, permitting individuals to choose the most appropriate remedy based upon particular environmental problems and efficiency requirements.

Benefits of Ceramic Coatings

Along with durability, ceramic coatings give superb hydrophobic buildings, enabling simple cleaning and upkeep. This water-repellent nature lessens the adherence of dirt, crud, and various other contaminants, which can extend the aesthetic allure and functionality of the surface. Ceramic coverings can significantly boost thermal resistance, making them optimal for pop over to this site applications that endure high temperature levels.

Ceramic finishings can add to power performance by mirroring warm, which is specifically valuable in automobile and industrial setups. On the whole, the various advantages of ceramic finishes make them a valuable investment for various applications, guaranteeing ideal performance and security.

Application Process

When using ceramic finishings, a careful method is vital to accomplish optimal results. A tidy surface area makes certain appropriate attachment of the covering.

When the surface area is prepped, the next action is to apply the ceramic coating. The finish ought to be applied in thin layers, as thicker applications can lead to uneven surfaces.

After application, the covering calls for a particular curing time, generally ranging from a click here for more couple of hours to a full day, relying on the product. Throughout this time, it is crucial to stay clear of exposure to dampness or contaminants. A gentle buffing might be needed after treating to improve the gloss and remove any high places. Adhering to these steps carefully will take full advantage of the performance and longevity of the ceramic covering, supplying a durable protective layer for the surface.

Maintenance and Durability

To guarantee the durability and efficiency of a ceramic finish, normal upkeep is necessary. Ceramic layers, recognized for their durability and safety top qualities, call for certain treatment routines to maximize their lifespan and efficiency. The primary step in maintenance includes routine cleaning with pH-neutral soap, staying clear of extreme chemicals that can break down the finish. It is a good idea to wash the lorry consistently, ideally every 2 weeks, to avoid the build-up of contaminants that can endanger the finish's honesty.

Along with regular washing, routine assessments are essential. Seek signs of wear or damage, such as hydrophobic buildings decreasing or surface area blemishes. A light polish may be applied to invigorate the coating without stripping it away. if needed - Ceramic Coating Denver.

In addition, the application of a booster spray can enhance the covering's click here for more hydrophobic impacts and recover its gloss. This is specifically advantageous for finishings that have actually remained in usage for an extensive period. Ultimately, by adhering to these upkeep methods, one can dramatically expand the life of a ceramic finishing, guaranteeing that it proceeds to offer optimum defense against environmental aspects and keep the visual allure of the lorry.

Verdict

In verdict, ceramic coatings represent a versatile solution for a range of applications, offering a variety of kinds such as silica, titanium zirconia, dioxide, and alumina. Generally, ceramic finishes contribute considerably to improving the resilience and performance of different surface areas throughout several markets.

Ceramic finishes have actually arised as a pivotal option across various sectors due to their one-of-a-kind buildings and applications.Ceramic layers are innovative safety services that have actually gotten popularity in various sectors, especially in automobile and aerospace applications. Ceramic layers can considerably enhance thermal resistance, making them perfect for applications that endure high temperature levels.

In general, the numerous benefits of ceramic finishings make them a valuable financial investment for various applications, ensuring ideal performance and security.

In conclusion, ceramic layers represent a functional service for an array of applications, providing a selection of types such as silica, titanium zirconia, dioxide, and alumina.

Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!